TESTED. PROVEN. TRUSTED.

At FG Screens, we don’t just claim performance, we prove it. ClearPlex® has undergone rigorous independent laboratory testing to validate its durability, clarity, and safety across a range of demanding conditions. Below, you’ll find verified results from multiple tests that demonstrate how ClearPlex® performs in real-world fleet and commercial applications.

LAB ABRASION TESTING

How Tough is Our Protective Laminate? We Put It to the Test.

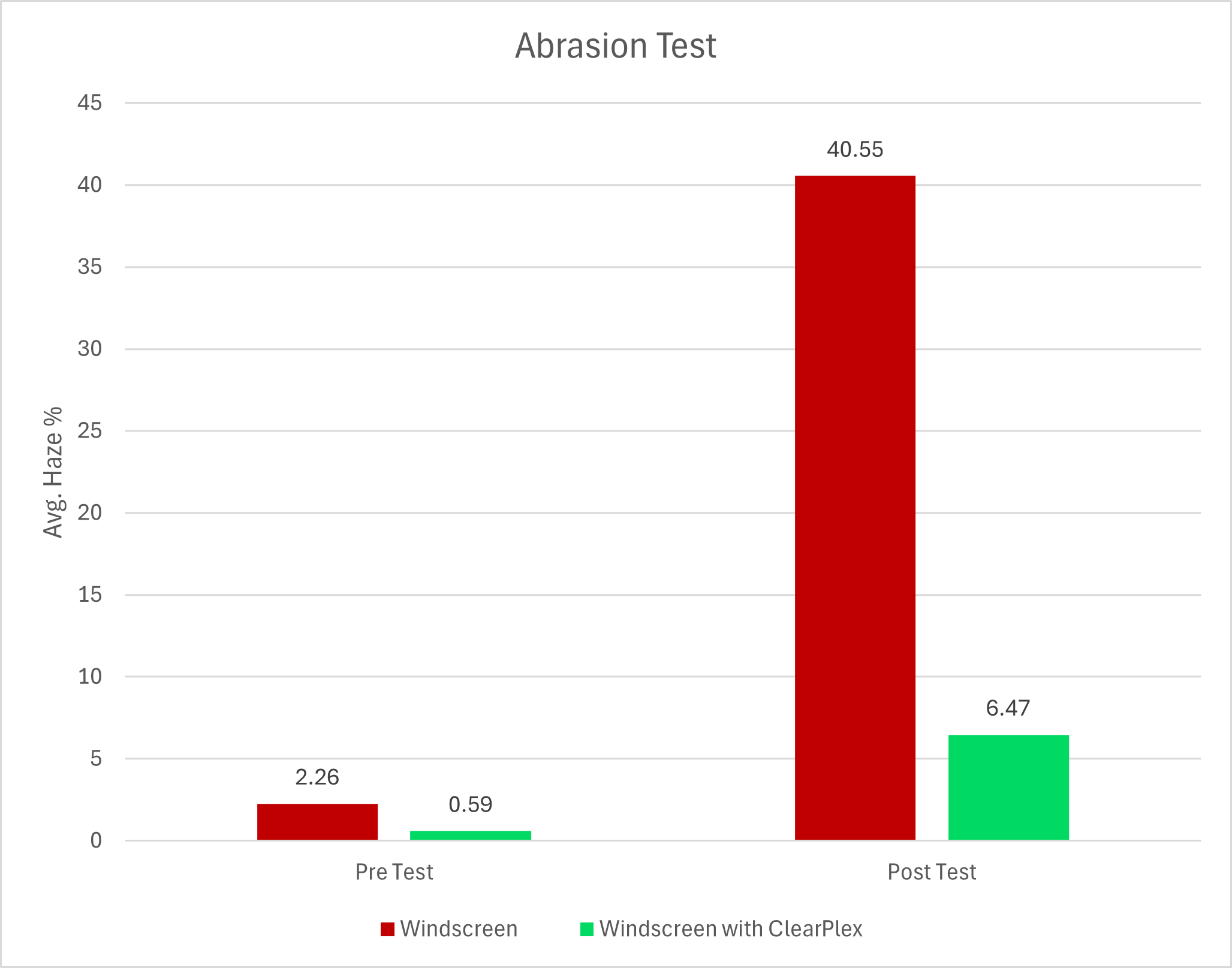

Standard laminated glass and laminated glass with ClearPlex® laminate were rubbed 1,000 times to simulate wear from dirt, wipers, and road debris. Haze levels were measured to assess abrasion resistance.

What This Means for You

ClearPlex® laminate offers longer-lasting windscreens with better visibility and improved clarity from day one, enhancing safety for personal, fleet, commercial, and mining vehicles.

Independent Testing

Testing was done by AWTA and UNSW ORLAB to global standards ASTM D1003, BS 2782-5, and UN-ECE R43.

The Results

ClearPlex® protected glass started at a low haze of 0.59 and rose slightly to 6.47. Untreated glass started at 2.26 and jumped to 40.55. The laminate reduced haze increase by over six times.

How Impact Resistant Is ClearPlex®?

ClearPlex® windscreen laminate was tested under real-world conditions to prove its strength against flying debris and road hazards.

In an independent impact test, a steel ball was swung into laminated glass, with and without ClearPlex® laminate, at speeds up to 180 km/h (5.2 Joules of energy). Unprotected glass cracked under lower impacts. With ClearPlex®, the glass stayed impact free, only the laminate showed a small surface mark.

This means fewer windscreen replacements, better visibility, and greater safety for personal, fleet, commercial, and mining vehicles.

Tested independently by LMT Engineering in South Africa. Proven protection when it matters most.

ClearPlex® Proven to Enhance Cab Window Safety

Independent testing on Comeng train cab side windows has confirmed the safety benefits of applying ClearPlex® to exterior glass surfaces. Conducted under FRA Type II standards, the tests simulated real-world threats including ballistic impacts and large object collisions.

Results

Ballistic Tests:

While ClearPlex® did not stop bullet penetration, it helped retain broken glass within the frame, reducing the risk of injury from flying shards.Impact Tests:

Windows treated with ClearPlex® and an interior anti-spall laminate significantly outperformed untreated glass. The treated glass resisted full penetration and prevented dangerous fragmentation, maintaining structural integrity even after multiple impacts.

ClearPlex® dramatically improves glass performance under stress, offering added protection in high-risk environments. FG Screens is proud to supply and install ClearPlex® as part of our commitment to advanced safety solutions.